When a machine stops without warning, everything around it stops too. Orders get delayed, workers wait, and money leaks fast.

Industry studies show that unplanned downtime can cost big companies over $1 trillion each year. For many factories, even one hour of downtime can mean more than $100,000 in losses. That’s before we count missed deliveries and upset customers.

Most breakdowns don’t happen because teams are careless. They happen because no one knew a problem was coming, a belt wearing out, heat rising inside a motor, a part shaking more than usual. Small issues hide until they suddenly explode into bigger ones.

That’s the challenge: If you can’t spot problems early, you can’t fix them before things fail.

Machine maintenance software helps here. It gives teams a clearer view of what’s happening inside equipment, helps them plan repairs at the right time, and reduces those surprise shutdowns.

In this post, we’ll look at:

- Why uptime drops

- How maintenance software helps prevent breakdowns

- Real numbers showing the impact

- What it takes to get value from these tools

What is Machine Maintenance Software and How Does it Help?

Machine maintenance app or software is a digital system that helps factories keep their equipment running reliably.

It tracks machine health, schedules preventive maintenance, records past repairs, and flags potential issues before failure. This helps reduce downtime, extend equipment life, and improve overall productivity. Below are the major ways it strengthens uptime in real, day-to-day operations.

1) It identifies issues early before machines fail

Most failures don’t appear suddenly. There are warning signs: temperature spikes, abnormal vibrations, slower cycle times, odd noises, or unusual energy usage. Without data, these early clues go unnoticed.

Maintenance software collects these signals through sensors or system logs and warns the team before things turn serious. That means a technician can tighten a bolt or replace a bearing long before the whole machine stops.

Why it matters:

- You plan small repairs instead of reacting to big breakdowns.

- Production schedules stay predictable.

- You avoid extended stoppages that throw deliveries off track.

A small fix today is always cheaper and less stressful than a major rebuild later.

2) It keeps preventive maintenance organized and timely

A lot of downtime happens not because teams can’t fix things, but because maintenance tasks get delayed or skipped. Paper schedules and spreadsheets are easy to ignore or misplace.

Predictive maintenance tools reduce downtime. They remind teams what needs to be serviced, when, and by whom. Work orders are clear, deadlines are visible, and nothing slips through the cracks.

What this changes on the shop floor:

- Tasks get done on time instead of piling up.

- Equipment runs closer to “like-new” condition.

- You avoid emergency work, which is always more expensive.

Over months, this steady rhythm dramatically reduces unplanned stoppages and extends asset life.

3) It ensures the right spare parts are ready

Even when a technician knows how to fix a problem, work stalls if the replacement part isn’t available. Many plants run into multi-day delays simply because a seal, belt, or motor isn’t in stock.

A facility maintenance software tracks spare parts, usage patterns, and reorder levels so teams always know what’s available. When inventory runs low, the system can automatically trigger purchase orders.

Result:

- Repairs happen immediately, not “when the part arrives.”

- No last-minute vendor panic.

- Less inventory waste from overstocking.

It’s a quiet change that prevents a surprising amount of downtime.

4) It helps technicians troubleshoot faster

When a machine stops, the clock starts burning money. One of the biggest delays is hunting for information, old notes, manuals, past repair history, or who worked on it last.

Maintenance platforms store everything in one place:

- Repair history

- Step-by-step checklists

- Photos or videos

- Manuals and wiring diagrams

So when something fails, technicians don’t start from scratch. They follow proven guidance and get the line running again sooner.

This also makes the team more resilient. You’re not dependent on one “expert” who remembers everything. Anyone on the team can take action.

5) It uncovers recurring issues you’d normally miss

Sometimes the same failure keeps happening, same gear, same operator shift, same hot summer month, but patterns stay invisible when information is scattered.

Equipment maintenance software highlights those patterns. You can finally see:

- Which assets break most often

- What root cause repeats

- Whether poor usage or environment plays a role

Once you know the pattern, fixing the real cause becomes much easier. You’re no longer putting out fires, you’re preventing them.

6) It helps maintenance and production work in sync

In many factories, production and maintenance work like separate islands. Production wants maximum output; maintenance wants time to service machines. When they don’t share information, equipment gets pushed until it fails.

Machine maintenance software provides shared visibility. Production planners can see which machines need service soon. Maintenance teams can see usage levels and adjust schedules.

For example, if a critical machine shows a temperature spike, production might slow it slightly or switch tasks before a failure happens. This shared rhythm keeps uptime high without slowing the business down.

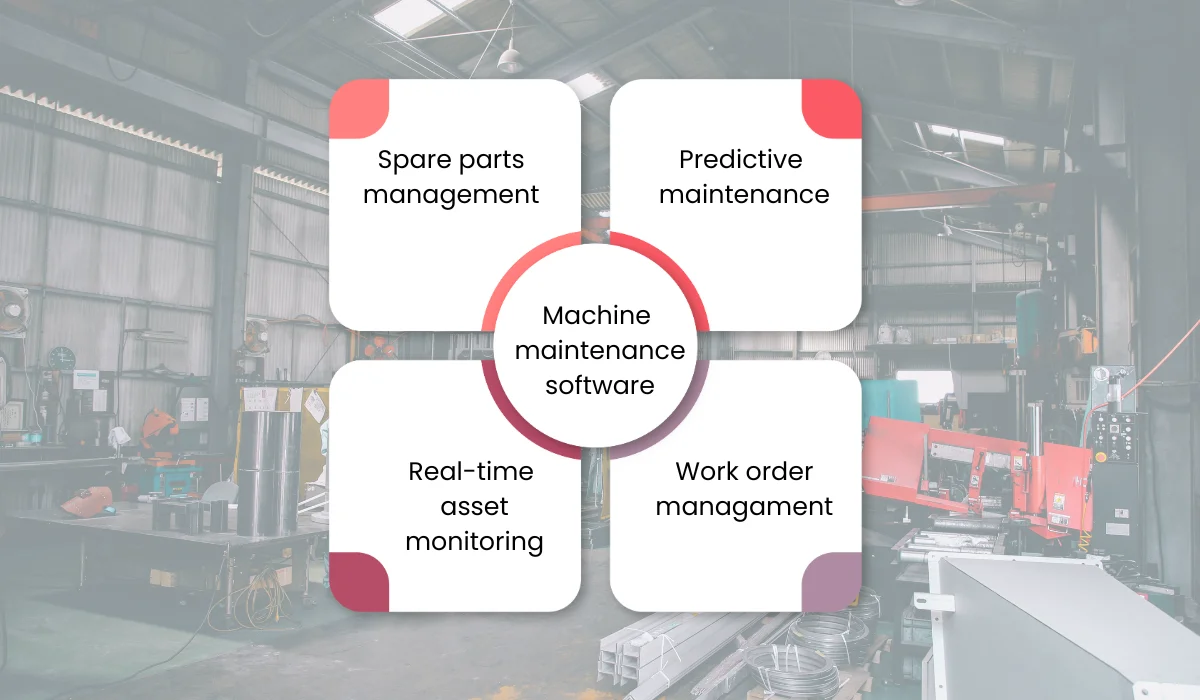

What Features to Look in Machine Maintenance Software

Buying industrial maintenance software can feel overwhelming. Everyone promises “more uptime,” but the details matter. These are the features that genuinely help in real situations.

1) Preventive + Predictive Maintenance Scheduling

Most plants know they should service machines on time… but keeping track manually is messy. Schedules get missed. Breakdowns follow. Maintenance software creates automatic schedules based on:

- Calendar dates (every 2 weeks)

- Usage (every 1,000 cycles)

- Condition (data signals like heat or vibration)

When a task is due, the right technician gets notified. If the machine shows unusual behavior, the software can pull that maintenance forward.

How this helps uptime:

- Small issues get handled before they snowball.

- You don’t need to remember what’s due, it tells you.

- Machines stay closer to “peak health,” so failures become rare.

2) Work Order Management: Clear Tasks + Faster Response

When a machine needs attention, the last thing you want is confusion. But that’s what happens with paper logs, WhatsApp, and hallway conversations. Technicians don’t know what’s urgent, what parts they need, or who’s working on what.

Work order management fixes that. A work order inside the software typically includes:

- The problem

- Priority (high/medium/low)

- Assigned technician

- Step-by-step instructions

- Required tools + parts

- Safety notes

- Deadline

Once finished, the tech closes the job and logs what happened.

How this helps uptime:

- Problems get to the right person fast.

- No task “disappears” because a paper got lost.

- You build a history you can refer back to.

- Supervisors can track progress instantly.

3) Real-Time Asset Monitoring (Condition Monitoring)

Some failures give warning signs such as strange vibration, unusual heat, increased energy use. Without sensors, you’d never know until the machine fails.

With monitoring, the software constantly watches asset health and sends alerts when readings drift from normal.

How this helps uptime:

- Problems are caught before they become breakdowns.

- Technicians fix during planned time, not at 2 AM.

- You minimize surprise downtime.

It’s like having health monitors on every critical machine.

4) Spare Parts + Inventory Tracking

A surprising amount of downtime happens not because the team can’t fix the problem, but because the spare part isn’t available.

This feature tracks:

- In-stock parts

- Where parts are stored

- Supplier details

- Reorder levels

- Lead times

Some systems even auto-generate purchase requests when levels run low.

How this helps uptime:

- No waiting days for a replacement.

- No guesswork about where parts are kept.

- Fewer emergency purchases at higher cost.

5) Mobile Access for Maintenance Techs

Machines don’t fail in an office. They fail on the shop floor, in a remote building, or outside. With mobile machine maintenance app, technicians can

- Receive new tasks on their phone

- See repair steps

- Look up manuals + past issues

- Upload photos

- Close jobs right there

How this feature of machine maintenance software improves uptime:

- Techs have answers without running around.

- Repairs start sooner.

- Work is recorded accurately at the moment.

It’s especially helpful for new hires, they can follow instructions instead of guessing.

6) Maintenance History + Documentation

Every fix creates knowledge. But if that knowledge stays in someone’s head or gets written on a scrap of paper, it’s lost. Maintenance management software stores history in one place:

- What failed

- Why it failed

- What fixed it

- How long it took

- Which parts were used

How this helps uptime:

- Teams troubleshoot faster next time.

- You see which machines are troublemakers.

- You make smarter repair/replace decisions.

7) Reporting + Insights

Good decisions need good data. Reporting shows patterns no one would notice manually.

Example insights:

- “Machine A fails more often during night shift.”

- “Preventive tasks cut breakdowns by 30%.”

- “These three machines cost 60% of the repair budget.”

How this helps uptime:

- You target root causes, not symptoms.

- You stop wasting effort on low-value fixes.

- You justify budgets with real evidence.

Data turns maintenance from reactive to strategic.

8) Integration With Other Systems

Maintenance touches purchasing, production, and finance. If your systems don’t talk, you lose time. Integration means the maintenance software connects with:

- ERP + inventory

- Production planning

- IoT sensors

How this helps uptime:

- Data flows automatically, fewer mistakes.

- Everyone sees the same picture.

- Maintenance can plan around production schedules.

You reduce conflicts and keep operations smooth.

Common Challenges When Adopting Maintenance Software (and How Teams Overcome Them)

Switching from paper logs or spreadsheets to a digital system sounds simple on paper. In reality, adoption takes planning, discipline, and some patience. Most teams face similar hurdles at the start, the good news is, they’re all manageable once you know where the friction usually comes from.

Let’s break down the common roadblocks and the practical ways companies get past them.

1) “We’ve always done it this way”

Many teams rely on tribal knowledge, experienced technicians know what to do, so no one feels the urge to change. When software comes in, it can feel like extra work or an unnecessary layer.

Why it slows things down:

Technicians may hesitate to enter data or follow new processes, so the system never gets the info it needs to be useful.

How companies overcome it:

- Start with small wins, track only the most critical machines first.

- Highlight how digital records help techs work faster, not harder.

- Involve technicians early so it feels like their tool, not management’s rulebook.

Once people see fewer breakdowns and easier troubleshooting, adoption improves naturally.

2) Poor or incomplete machine data

If asset information isn’t entered correctly in the beginning, the software can’t give accurate recommendations.

Why it matters: Bad data leads to unreliable schedules and confusing reports.

How teams handle it:

- Start with only your most important equipment.

- Build asset profiles in batches instead of all at once.

- Assign ownership to one person or role responsible for regular data checks.

3) Lack of training

It’s common to assume people will “figure it out.” They usually don’t, especially when the shop floor is busy.

What goes wrong:

- Features get ignored

- Only a few people know how to use the system

- Work orders go back to manual tools

What works better:

- Hands-on training for every shift

- Simple how-to guides for common tasks

- Practice sessions before going live

Training doesn’t have to be complicated, it should be just consistent.

4) Technicians forget to log work

When someone is under time pressure, logging a repair can feel like an extra step. Over time, missing data leads to weak insights and broken history.

How preventive maintenance software for small factories can fix this:

- Use mobile apps so logging takes seconds, not minutes

- Simplify forms, only collect what actually matters

- Celebrate accuracy (not just speed)

When logging becomes easy, adoption improves.

5) Too many features, not enough focus

Some platforms offer everything from IoT dashboards to AI forecasting. It’s tempting, but overwhelming.

Why it causes trouble: Teams get stuck trying to learn everything instead of mastering the basics.

Better approach:

- Focus on core features first: preventive scheduling + work orders + inventory

- Add advanced modules later

- Tie every new feature to a real business problem

Software works best when it solves pain points in the right order.

6) Integration friction

Connecting maintenance software with ERP, inventory, or production tools can take longer than expected.

Why:

- Data formats differ

- Naming conventions don’t match

- No one “owns” the integration work

How teams solve this:

- Clean up data before integration

- Sync only what matters (e.g., parts + equipment IDs)

- Assign a single owner to coordinate

Start small; expand later. Integration doesn’t have to be perfect to be useful.

7) Expecting results overnight

Even the best system needs time to build data and show trends. Some teams get discouraged when uptime doesn’t jump immediately.

How to stay steady:

- Track progress month by month

- Celebrate small gains such as fewer emergency repairs, better spare-parts visibility

- Use reports to show the improvements clearly

Over time, the system becomes more accurate… and more valuable.

Conclusion

At the end of the day, keeping machines running is about keeping your business moving. When equipment goes down, everything gets messy, delays, overtime, unhappy customers, extra costs. Nobody wants that.

The best machine maintenance software for the manufacturing industry just helps you stay ahead of problems. It shows what’s going on with your machines, reminds you when work is due, and helps you fix issues before they turn into breakdowns.

If you’re unsure where to begin, start small. Pick one area that gives you the most trouble, maybe it’s unplanned breakdowns, spare-part chaos, or unclear task tracking. Then explore how a maintenance tool could help you fix just that one piece. You’ll learn what works for your team before rolling out anything bigger.

Also, involve the people who’ll use the software every day. Their feedback will tell you more than any brochure, what slows them down, what data they wish they had, and what actually helps on the shop floor.

And before choosing a machine maintenance software, ask vendors practical questions:

- How quickly can we go live?

- Does it work on mobile?

- Will it work with our current systems?

- How do you support us after onboarding?

The goal isn’t to buy software, it’s to build a maintenance approach that gives you fewer surprises and more predictable days. Your machines will thank you. Your team might, too.

FAQs

What problems does machine maintenance software solve?

It helps reduce unplanned breakdowns, keeps maintenance work organized, tracks machine history, and ensures you never miss a service. This leads to fewer interruptions, lower repair costs, and better machine performance.

Does machine maintenance software work offline or on mobile?

Most modern tools offer mobile apps, and some also support offline mode. When the device reconnects to the internet, the data automatically syncs. Availability depends on the vendor, so it’s best to confirm before choosing.

How much does machine maintenance software cost?

Cost varies based on features, number of users, and deployment type. Some charge per user monthly, while others follow a subscription or enterprise model. Smaller teams may pay a few thousand per year; large plants may pay more.

What features should I look for in maintenance software?

Useful features include preventive maintenance scheduling, work order management, asset history, spare-parts tracking, and reporting. Mobile access and alerts are also helpful for daily use.

What reports or dashboards does equipment maintenance software provide?

Typical dashboards show work order status, upcoming tasks, downtime trends, maintenance costs, asset performance, and spare-parts usage. These insights help you plan better and improve machine uptime.