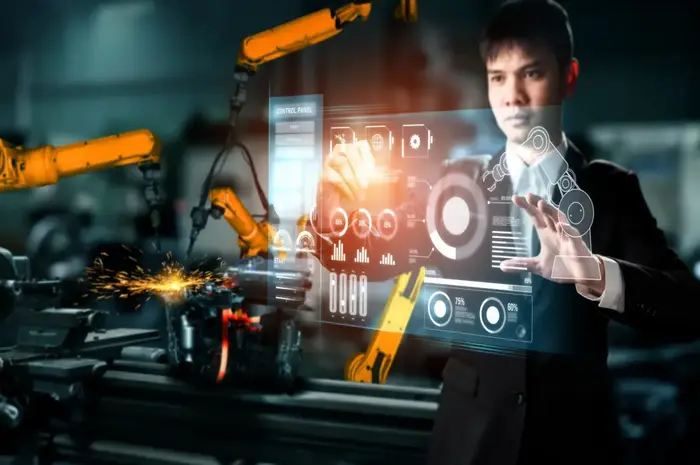

AI in the manufacturing sector is essential for achieving Industry 4.0. That’s why manufacturers are investing heavily in this technology. Emerging technologies like IoT and automation are further fuelling their interest as they complement AI. Let’s explore some of the ways AI is already used in this sector.

AI Solves 3 Key Problems of Manufacturing Industry

Manufacturers generate massive amounts of data (1812 petabytes a year, according to a Deloitte survey). This data holds the key to solving critical challenges in this industry such as material procurement or cutting maintenance costs. However manually analyzing this huge and complex data is impossible.

That’s where AI comes in. It gives the ability to process vast amounts of data in seconds, making it an essential tool to address key problems. Majorly, it is used to address problems related to:

- Manual operations

- Market trend predictions for smart scheduling and on-demand manufacturing

- Quality produce and inspection

How is AI Used in Manufacturing?

1. Smart Robots

Factories filled with industrial robots – that’s how we have always pictured the future of manufacturing, right? Well, those bulky machines that only automate repetitive tasks are slowly becoming history.

Manufacturers need robots with brains. AI technologies like computer vision and natural language processing are making it possible. These new AI-powered robots are called co-bots. They can see, decide, and even work alongside humans to

- Assist human workers in assembly and production tasks

- Ensure safety by detecting real objects in the workspace

- Work in dynamic manufacturing environments

- Identify real-time defects in products

- Safely transport materials

Unlike traditional robots, co-bots are easy and cheap to deploy. Big companies like Procter & Gamble and Amazon are already using them to ease their teams’ work.

2. Predictive Maintenance

Maintenance costs are a major headache for manufacturers. They end up spending a big chunk of their production budget—around 15-40%—on fixing and maintaining their equipment or fleet, both directly and indirectly. This isn’t something they can skip because if equipment breaks down, production stops, and revenue takes a hit.

That’s where AI comes in handy. By using AI for predictive maintenance, manufacturers can predict when machines might fail early on. They can save time and money by fixing things before they break down completely. Plus, it reduces accidents in the factory, making the factory a safe place for workers.

3. Demand Management

In the manufacturing industry, there’s a ton of data floating around which can help in predicting what customers want. By using AI, manufacturers can take advantage of this data and get benefits like:

- It prevents running out of stock or having too many products in the inventory.

- It ensures they always have what customers want when they want it.

- It helps in making the right products to meet sales goals and customer needs.

4. Generative Design

The manufacturing industry looks for smart manufacturing techniques and technologies to create innovative products on a budget. But this takes time and resources which can slow down the production.

AI-powered generative design tools let design engineers explore multiple design possibilities or refine existing ones in less time. It also helps them choose the right materials according to the desired criteria.

This use of AI in manufacturing hit three goals at once- designing products at scale, minimizing waste and production costs, and quickly releasing products in the market.

5. Error and Fault Detection

When there are lots of products or machines to monitor, it’s tough for human eyes to catch every error. AI-powered error detection systems are useful here. They can spot defects that even humans might miss, like color inconsistencies. Smart machine learning algorithms make these systems faster and more accurate, making them super helpful for factories with busy production lines.

6. Customer Support

AI isn’t just for the factory floor anymore—it helps in connecting with customers too. Take customer service, for instance. Manufacturers are using AI to understand how customers feel about their products and what they want in the future. This info is gold—it helps companies improve their products and come up with new ideas.

AI-powered chatbots and support systems are making customer service further better, tackling problems quickly no matter when or where they pop up. This frees up support teams to focus on more specific issues and stop them from getting worse.

Read More About: How AI-Powered Sentiment Analysis is Boosting Customer Experience in Digital Age

7. Order and Delivery Management

In the digital world, customers expect everything at lightning speed. They want to quickly place their order, stay informed about their order status, and expect a superfast delivery. However, efficiently managing orders and deliveries is quite challenging for manufacturers and brands.

Traffic jams and inefficient scheduling of drivers are a few reasons behind this challenge. But AI can ease the job. It analyzes the traffic and weather conditions in real time to identify the best delivery route. By integrating with telematics, AI also helps in knowing the status of drivers and their vehicles to perfectly plan the next delivery.

This use of AI in order and delivery management not only saves businesses time and money on fuel but also ensures faster deliveries and fewer delays.

The Future of AI in Manufacturing

The above use cases prove that the impact of AI in manufacturing is more than what we have imagined. However, the future will not look like factories fully run by AI-powered robots (at least not now.)

The real future of AI in manufacturing will be much more practical. Super-powered assistants powered by machine learning and other AI technologies will work alongside humans, bringing in more efficiency.

Machines will get smarter than today to predict problems, be adaptable to unexpected situations, and capable of making real-time decisions just like us.

Conclusion

The introduction of AI in manufacturing is a game-changer for every manufacturer worldwide. It is an efficient and advanced route to run operations smoothly while saving both time and money in production. When combined with machine learning, IoT, and automation, AI takes industries closer to smart manufacturing, offering real benefits like efficiency and innovation.

Therefore, embracing AI isn’t just a choice—it’s essential to make the manufacturing sector smart and connected.