This growing complexity has made one thing painfully clear: traditional systems, no matter how automated, are just not enough anymore.

That is where Agentic AI comes in, not just as an improvement but as a game-changer. One where digital agents can think, act, and learn on their own, relieving humans of the burden of reacting to every little change.

In this blog, we will walk through what Agentic AI means in a supply chain context, how it is different from the AI you might already be using, and how it is making a real difference across industries, from retail to pharma.

What is Agentic AI in the Context of Supply Chains?

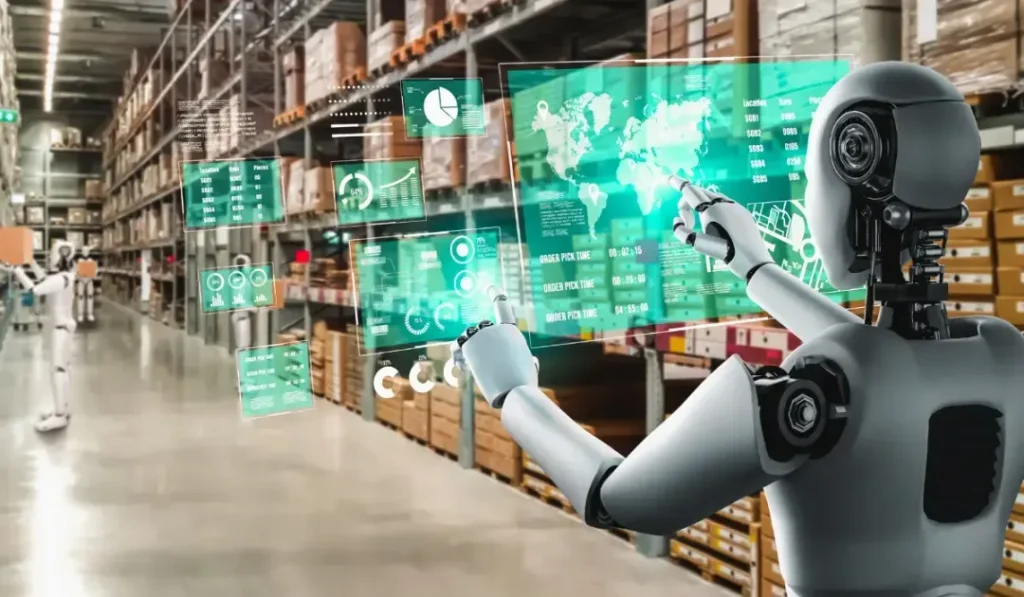

Agentic AI is all about providing software with the capacity to act autonomously, such as a digital peer that is proactive rather than simply reactive. These agents do not sit around waiting for instructions on what to do. They watch what is happening, make real-time decisions, act, and then learn from the result so that they can do it better on the next pass.

In supply chain operations, this holds major significance. Suppose you are coordinating shipments between continents. Port delays are being experienced due to unfavorable weather. In normal circumstances, a human would have to check, replan, rebook, and notify the customer

Agentic AI makes it possible for a software agent to sense the delay, identify an alternate route, redirect logistics, and notify all parties concerned, without human intervention. It is not only intelligent. It is independent.

How Agentic AI Stands Out from Conventional AI Systems

Let’s not mix Agentic AI with other types of AI that are already implemented. And besides, a lot of businesses already have AI that is used to examine data, predict trends, or streamline processes. The difference, however, is autonomy and action.

Most conventional AI systems are analytical. They are great at number-crunching, trend-spotting, and making predictions. But after they have performed their task, it is left to human operators to translate the output and determine what to do next.

Agentic AI takes this much larger step. It does not just provide suggestions, it follows through. These models of artificial intelligence watch, act, make decisions, and then learn from the results to better perform actions in the future. This closed-loop system is what makes the system more intelligent over time without having to be constantly reprogrammed or updated by humans.

Suppose that you have a digital supply chain assistant who is not only telling you, “There will be a shipping delay,” but also saying, “There is a delay at port X, so I have reshipped your product through port Y and sent word to your customer of the new shipping schedule.”

This is the level of intelligence and ingenuity that Agentic AI introduces, and that is what sets it apart.

Why Modern Supply Chains Are Ready for Agentic AI

Global supply chains today operate in an environment filled with uncertainty. A political conflict in one part of the world, a natural disaster elsewhere, or even a social media trend can have ripple effects that reach your warehouse or disrupt your manufacturing line.

And while businesses have invested in supply chain technologies over the years, many systems still depend on rigid rules and manual intervention. These older systems weren’t built for the speed, scale, or unpredictability of today’s world.

Agentic AI addresses these limitations by introducing a new layer of intelligence and automation that can:

- Adapt in real time to dynamic changes, minimizing the fallout from disruptions

- Easily scale to handle vast datasets and drive decision-making across global operations

- Proactively identify risks and opportunities instead of reacting to problems after they occur

- Automate routine decisions and tasks, freeing up human teams for higher-level strategic work

This combination of speed, autonomy, and foresight is exactly what supply chains need in a world where every second counts and every decision affects the bottom line.

Agentic AI at Work: Real-World Impact on Supply Chains

Let’s now take a closer look at how businesses are already implementing Agentic AI to drive real, measurable impact across different aspects of the supply chain.

1. Demand Forecasting and Inventory Optimization

Forecasting demand accurately is one of the most difficult and critical tasks in supply chain management. Get it wrong, and you either have warehouses full of unsold stock or empty shelves when customers are eager to buy. Both situations are costly and damaging to the brand.

How Agentic AI Helps:

Agentic AI agents continuously collect and analyze data from a wide array of sources, including historical sales, current trends, social media, seasonal changes, news events, and more. They create detailed, adaptive demand forecasts and adjust inventory levels accordingly.

These agents do not wait for monthly meetings or static reports. They:

- Track every sales event and supplier update the moment it occurs

- Ensure timely restocking with automated triggers for low inventory

- Transfer stock between locations to meet local demand variations

- Control storage expenses without compromising on service levels

Real-World Impact:

A global retail chain rolled out agentic AI across 300+ locations. Within months, they saw a 25% reduction in overstock, an 18% drop in stockouts, and significantly lower inventory costs, without sacrificing customer satisfaction.

2. Autonomous Procurement and Supplier Management

Procurement is a high-stakes operation. Teams must monitor supplier performance, negotiate terms, manage risk, and respond quickly when things go wrong. Doing all this manually is not just time-consuming, it’s error-prone and reactive.

How Agentic AI Helps:

AI-driven procurement agents are capable of managing a broad spectrum of tasks independently. They evaluate supplier reliability, monitor price fluctuations, initiate purchase orders, and even handle negotiations based on preset parameters.

For example, if a supplier’s facility is suddenly impacted by a geopolitical event, the AI agent can quickly:

- Identify the issue

- Find an alternate supplier

- Reassess timelines and cost implications

- Redirect the purchase; all in real time

3. Smarter Logistics and Route Optimization

Transporting goods efficiently remains one of the most complex and expensive parts of the supply chain. Traffic conditions, fuel costs, weather delays, and regulatory changes can all affect timelines and profits.

How Agentic AI Helps:

Logistics agents use live data, such as GPS tracking, weather forecasts, and port congestion reports, to make smart, timely decisions. These agents:

- Suggest optimized delivery routes

- Reassign loads based on real-time disruptions

- Adjust truck schedules to reduce idle time

- Sync with warehouse agents to streamline loading/unloading

Real-World Impact:

A European logistics provider deployed AI agents to manage their delivery network. They reported a 30% reduction in delivery delays and a 12% decrease in fuel usage, thanks to dynamic, real-time route adjustments.

4. Dynamic Production Planning and Scheduling

Manufacturing lines are vulnerable to unexpected issues, machine breakdowns, last-minute order changes, or delays in raw material deliveries can throw production off course.

How Agentic AI Helps:

AI agents integrate with manufacturing systems and keep tabs on everything: machine health, material availability, workforce shifts, and order backlogs. When disruptions occur, the agent:

- Instantly reschedules production

- Reallocates resources

- Update timelines for delivery

Real-World Impact: An automotive manufacturing enterprise adopted agentic AI for its assembly line planning. It achieved a 22% decrease in downtime, 15% improvement in throughput, and better delivery adherence, all while reducing overtime hours.

5. Proactive Risk Detection and Disruption Response

Modern supply chains are fragile. Events across the globe can impact operations in unpredictable ways. Waiting for human-led risk assessments can cost valuable time.

How Agentic AI Helps:

To anticipate disruptions, risk agents track information from weather feeds, news outlets, supplier portals, and social platforms. When they detect a threat, they do not just raise an alert; they take action. They assess the potential impact and initiate mitigation plans automatically.

Real-World Impact:

During the early days of the COVID-19 pandemic, a pharmaceutical enterprise used Agentic AI to spot early warning signs of factory shutdowns in China. The system triggered contingency plans and shifted production to facilities in Europe and India, avoiding the product shortages that plagued competitors.

Final Thoughts

Agentic AI is not just another tech trend. It is a powerful tool that is already helping businesses simplify the complex, adapt faster, and build resilience in ways that were impossible just a few years ago.

If you are still relying on static tools, rigid systems, or constant manual oversight, now’s the time to rethink how your supply chain runs.

The question is not about the necessity of Agentic AI. The question is: how soon will you be ready to let it take the wheel?

Are you ready to make the shift? Let’s connect and explore how Agentic AI can help you build a supply chain that is ready for the future, autonomous, agile, and built to thrive in uncertainty.