Smarter Maintenance for Smarter Manufacturing

Automate maintenance, track spares, and resolve issues faster with our machine maintenance app.

See MMA in Action

Trusted By 1100+ Clients Globally

What is Machine Maintenance Application (MMA)

A digital-first maintenance control center that replaces scattered spreadsheets and manual tracking with structured, smart workflows.

It connects machines, parts, people, and vendors into one platform giving you the visibility and control across every production line.

Whether it’s preventive servicing, spare part availability, or vendor coordination, MMA puts your entire maintenance process on auto-mode,

letting you focus on uninterrupted production, not paperwork.

Why Manufacturers Trust Our Application

In manufacturing, even a 10-minute machine breakdown can ripple across shifts, deliveries, and profits. MMA helps teams avoid that chaos. By replacing scattered logs and paper-based tracking, it builds a preventive, data-driven approach that keeps operations predictable, auditable, and always on schedule.

Plant Without MMA

Plant Without MMA

Missed maintenance tasks

Manual schedules and human error often lead to service delays and machine failures.

No visibility into part consumption

Teams struggle to keep track of real-time usage of spares and consumables.

Delayed servicing and response

Lack of workflows causes slow action and longer machine downtimes.

Paper logs with no accountability

Important service records are lost in files and paper-based tracking systems.

Plant With MMA

Plant With MMA

Everything tracked and scheduled

All maintenance activities are digitally logged, and timely notifications are automated.

Full view of parts, oil, and inventory

Inventory levels, requests, and consumption data are always visible and up to date.

Ticket-based vendor workflow

Issues can be raised, assigned, and resolved through structured workflows.

Historical logs at your fingertips

Complete servicing history of each machine is instantly accessible and searchable.

What Our Clients Have Achieved

( And You Can Too )

See how businesses like yours turned maintenance challenges into measurable wins with our application.

35%

Less Unplanned Downtime

Timely scheduling and proactive issue tracking helped cut sudden breakdowns drastically.

70%

Increased Task Throughput

Automated workflows and real-time visibility enabled each supervisor to close more tasks, faster.

25%

Reduced Spare Part Waste

Smart inventory tracking prevented over-ordering and ensured timely availability of critical components.

100%

Simplified Audit Compliance

Digital service logs and vendor history made inspections smooth, with zero delays or penalties.

How Machine Maintenance App Helps Your Team

As factories get smarter and more connected, even a small disruption can ripple through production, quality, and delivery. MMA (Machine Maintenance Application) is built to help you prevent those disruptions. Here’s how our app helps you.

Centralizes Machine Records

Maintain complete, up-to-date digital profiles for every machine across locations: track specifications, service schedules, usage logs, and check-in/check-out history in one place.

Automates Maintenance Schedules

Set up daily, weekly, or monthly maintenance schedules that trigger automatically. Instantly log breakdowns with complete context, so nothing slips through the cracks.

Standardizes Workflows with Checklists

Create and assign custom checklists for each asset to ensure consistency in servicing. Eliminate guesswork and reduce reliance on tribal knowledge or memory.

Tracks Inventory in Real Time

Raise part requests directly from the application. Know what’s in stock, what’s used, and what’s needed, avoiding both delays and excess inventory.

Streamlines Ticket Management

Turn every issue into a clear, trackable ticket. Assign it, resolve it, and keep teams aligned with real-time status updates and role-based ownership.

Monitors Vendor Performance

Assign vendor, track activities, and service timeline, so you always choose the right partner and stay compliant.

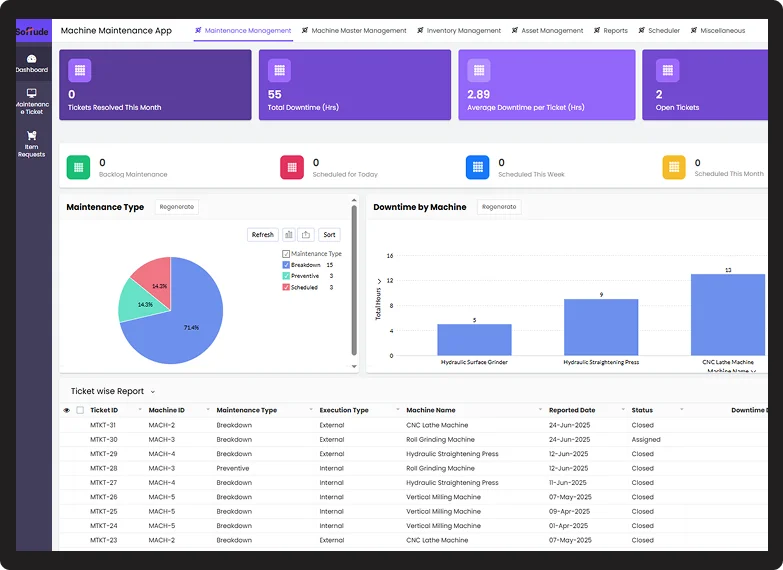

Provides Live Dashboards & Reports

Track open, resolved, or overdue tickets, view downtime by machine, and monitor asset health in real time, from a centralized dashboard.

-

Centralizes Machine Records

Centralizes Machine Records

-

Automates Maintenance Schedules

Automates Maintenance Schedules

-

Standardizes Workflows with Checklists

Standardizes Workflows with Checklists

-

Tracks Inventory in Real Time

Tracks Inventory in Real Time

-

Streamlines Ticket Management

Streamlines Ticket Management

-

Monitors Vendor Performance

Monitors Vendor Performance

-

Provides Live Dashboards and Reports

Provides Live Dashboards and Reports

Centralizes Machine Records

Maintain complete, up-to-date digital profiles for every machine across locations: track specifications, service schedules, usage logs, and check-in/check-out history in one place.

Get a Custom Quote

Automates Maintenance Schedules

Set up daily, weekly, or monthly maintenance schedules that trigger automatically. Instantly log breakdowns with complete context, so nothing slips through the cracks.

Get a Custom Quote

Standardizes Workflows with Checklists

Create and assign custom checklists for each asset to ensure consistency in servicing. Eliminate guesswork and reduce reliance on tribal knowledge or memory.

Get a Custom Quote

Tracks Inventory in Real Time

Raise part requests directly from the application. Know what’s in stock, what’s used, and what’s needed, avoiding both delays and excess inventory.

Get a Custom Quote

Streamlines Ticket Management

Turn every issue into a clear, trackable ticket. Assign it, resolve it, and keep teams aligned with real-time status updates and role-based ownership.

Get a Custom Quote

Monitors Vendor Performance

Assign vendor, track activities, and service timeline, so you always choose the right partner and stay compliant.

Get a Custom Quote

Provides Live Dashboards & Reports

Track open, resolved, or overdue tickets, view downtime by machine, and monitor asset health in real time, from a centralized dashboard.

Get a Custom Quote

Testimonials

What Our Clients Say

Factory Admin

Pharmaceutical Plant, Mumbai

"Before MMA, audits were a mess. Now we have proper checklists and digital records, so we’re always ready."

Maintenance Supervisor

Textile Manufacturing Unit, Surat

"Everything is in one place now, tickets, part requests, job tracking. I don’t have to chase anyone anymore."

Plant Head

Auto Components Manufacturer, Pune

"Since we started using this maintenance app, our machines have had fewer breakdowns and everything feels more organized. Definitely worth..."

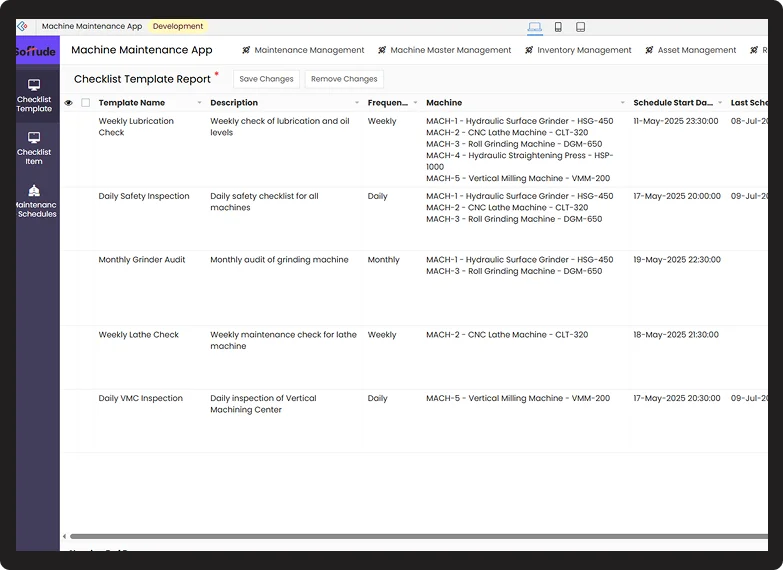

What’s Inside the MMA

Maintenance Management

Track downtime, ticket status, and maintenance types in real-time. Gain instant insights into machine breakdowns, costs, and task execution, all from a centralized, visual dashboard.

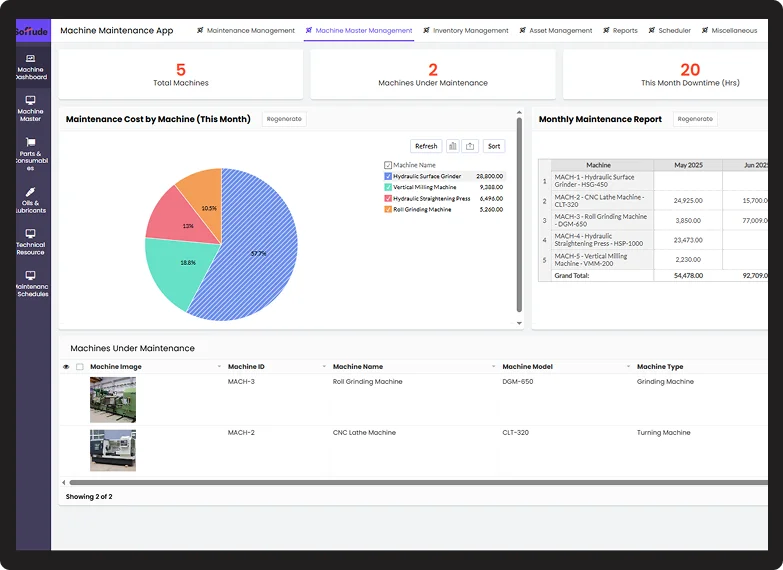

Machine Master Management

Maintain a centralized, visual record of every machine with complete details and service logs. With built-in cost visibility, you can also track monthly maintenance cost, and make smarter decisions backed by real data.

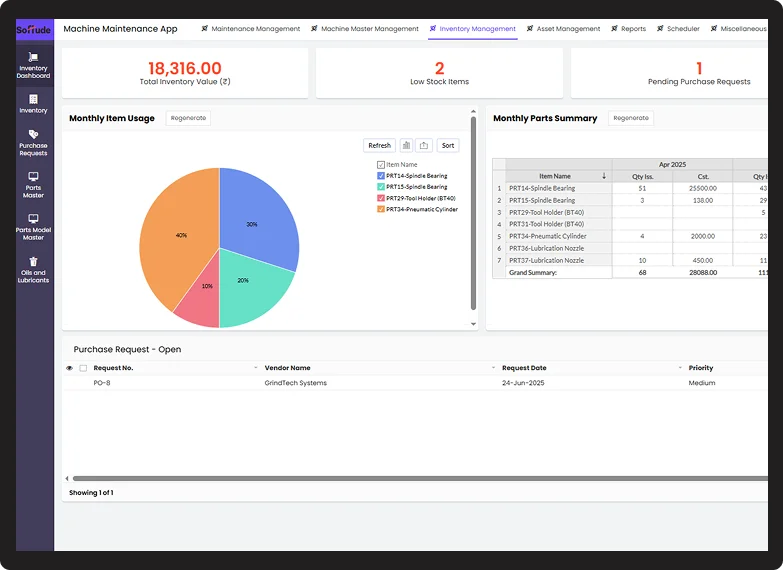

Inventory Management

Track every part, spare, and lubricant, from stock availability to usage logs and reorder needs. Avoid last-minute shortages and overstocking with smarter inventory control linked to actual maintenance activity.

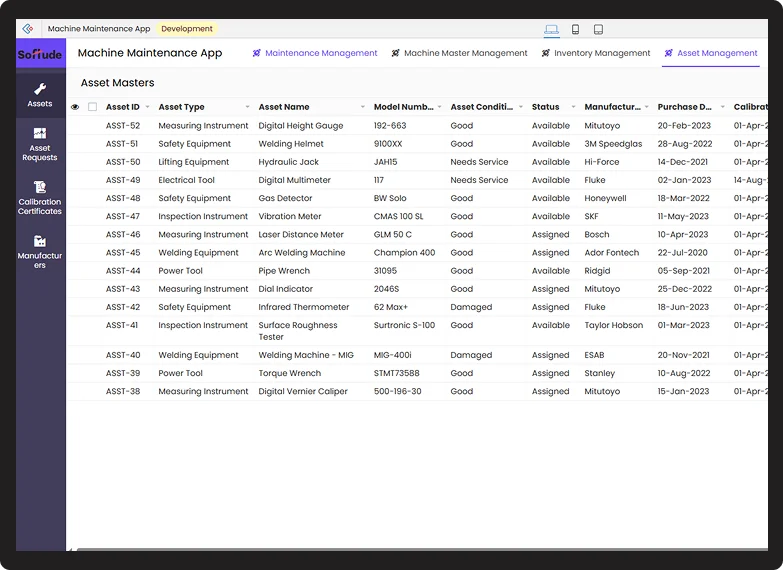

Asset Management

Log every asset, track its location, usage, and condition in real time. Whether it's a shared tool or a critical machine, you know exactly where it is, who's using it, and when it’s due for check-in or service.

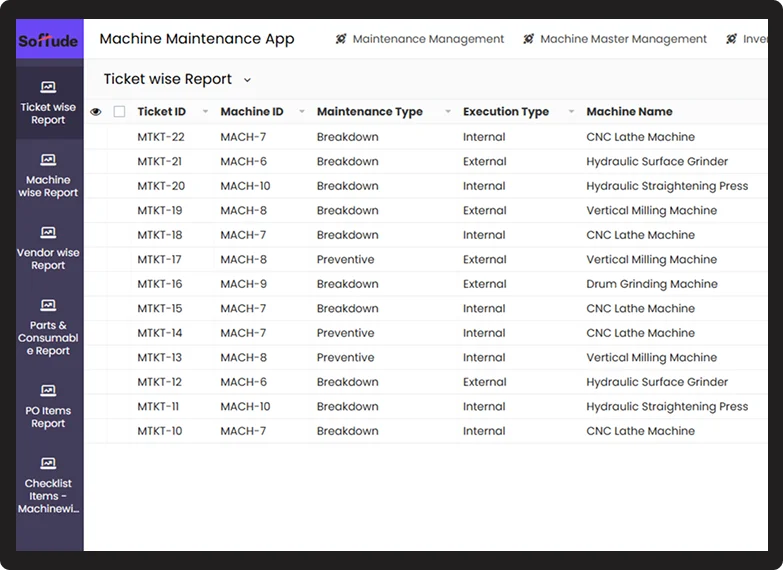

Reports

Pull actionable reports by machine, ticket, vendor, or parts and consumables. Get clear data on breakdowns, costs, and closures so you can make faster, better-informed decisions.

Scheduler

Automate daily, weekly, or monthly maintenance with predefined checklists. Assign schedules by machine, track due dates, and ensure timely inspections without missing a beat.

Maintenance Management

Track downtime, ticket status, and maintenance types in real-time. Gain instant insights into machine breakdowns, costs, and task execution, all from a centralized, visual dashboard.

Machine Master Management

Maintain a centralized, visual record of every machine with complete details and service logs. With built-in cost visibility, you can also track monthly maintenance cost, and make smarter decisions backed by real data.

Inventory Management

Track every part, spare, and lubricant, from stock availability to usage logs and reorder needs. Avoid last-minute shortages and overstocking with smarter inventory control linked to actual maintenance activity.

Asset Management

Log every asset, track its location, usage, and condition in real time. Whether it's a shared tool or a critical machine, you know exactly where it is, who's using it, and when it’s due for check-in or service.

Reports

Pull actionable reports by machine, ticket, vendor, or parts and consumables. Get clear data on breakdowns, costs, and closures so you can make faster, better-informed decisions.

Scheduler

Automate daily, weekly, or monthly maintenance with predefined checklists. Assign schedules by machine, track due dates, and ensure timely inspections without missing a beat.

Built for the People Who Keep Factories Running

Our machine maintenance app is designed for manufacturers who want to run lean, smart, and interruption-free.

Gain oversight of plant-wide maintenance with centralized control and insights.

Plan, assign, and monitor service activities with a digital-first approach.

Ensure uptime and reduce service interruptions that impact production timelines.

Manage machines and service records more efficiently with fewer errors.

Simplify documentation, coordination, and audit readiness with digital logs.

Frequently Asked Questions (FAQs)

Check out answers to some of the most common questions or queries.

Not at all. Our machine maintenance system can be implemented in phases, running alongside your existing process until your team is fully transitioned, ensuring zero downtime during onboarding.

Yes. We help you import historical machine, part, and ticket data so your past records are not lost. Everything is mapped and organized during setup.

MMA supports API-based integration and can connect with your ERP or inventory software for a smoother flow of part requests, stock updates, and reporting.

Yes. Our custom machine maintenance application works across desktop and mobile devices, allowing your on-ground staff to raise tickets, check checklists, or update logs directly from the shop floor.